Building a Beautiful City

Creating an Ideal Life

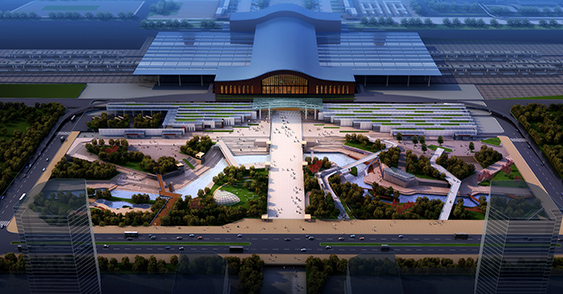

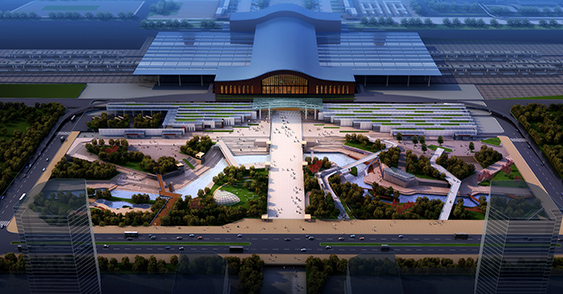

Business Section:Smart Transport

Location:Harbin, Heilongjiang Province

Project Completion Date:12, 2013

Participating Mode:Design

Project Value:Harbin’s Intelligentization Reaching National Leading Level

The First Phase of Haxi Smart System in Harbin, Heilongjiang province is located in Harbin West Railway Station, the important city gate in southwestern Harbin, covering an area of 18.3 square kilometers. It was put into operation with Harbin West Railway Station Integrated Transport Hub. As the model project in Harbin West Railway Station to apply Internet of Things, the smart system of Haxi integrated transport hub is a regional information handling center, mainly focusing on traffic and passenger flow management. STEC was responsible for designing the smart system’s IT center of “Smart West Harbin”. Using this system helped Haxi to become a smart society with “smart traffic, smart city inspectors, smart securities, and smart communities”. The IT center can show all real-time traffic information, 24 hours surveillance, transport scheduling, offer parking information, and deal with emergency through the smart system. This can eventually help Harbin Railway Station to operate and maintain core areas, respond to disaster or emergencies, regulate traffic and share information, schedule transport and govern the city comprehensively.

As the leading enterprise in domestic smart design, STEC has successfully completed projects like Information Management System of Shanghai Hongqiao Integrated Transport Hub, Shanghai Road Traffic Information Collection and Distribution System, and Smart Management System in East Zhengzhou Station, Henan Province, continuously racing ahead in the domestic smart transport industry.

Business sector: Roads and bridges

Location: Anyang City of Henan Province

Commencement time: December 2021

Participation mode: BOT mode

The Bid AHTJ-3 of Anyang-Hebi section of Anyang-Xinxiang Expressway will effectively relieve the traffic pressure of the Beijing-Hong Kong-Macao Expressway and optimize the operation efficiency of the road network. It will enhance the Henan-Hebei transportation corridor, improve the layout of regional road network, and strengthen the connection between North Henan and Zhengzhou metropolitan road network.

The Bid AHTJ-3 of Anyang-Hebi section of Anyang-Xinxiang Expressway is as long as 18.84 km. The bid involves 16 bridges, 3 middle bridges, 3 overpasses, 29 culverts, and 2 medium and long tunnels, with the bridge-tunnel ratio over 40%. This project, an important section of the highway network planning in Henan Province (2021-2025), will further improve the “米+井+人” shaped integrated transportation corridor in Henan Province upon its completion. It plays a significant role in solving the expressway connection between Anyang and Hebi and promoting the regional economic development.

Business sector: Roads and bridges

Location: Shaoxing City, Zhejiang Province

Commencement time: September 2021

Participation mode: PPP mode

The PPP project of connection line between Hangzhou-Jinhua-Quzhou Expressway to Hangzhou-Shaoxing-Taizhou Expressway is jointly undertaken by Zhejiang Communications Investment Co., Ltd., Zhejiang Communications Engineering Co., Ltd., STEC Shanghai Infrastructure Co., LTD., and Shanghai Road and Bridge Co., Ltd. The project starts from the north side of Zhangjiafan Hub of Hangzhou-Jinhua-Quzhou Expressway and ends at Fuquan Hub of Hangzhou-Shaoxing-Taizhou Expressway. The route is as long as 22.028 km. The main construction tasks involve subgrade, bridge, culvert, tunnel, pavement, traffic safety, afforestation, etc.

The connection line of Hangzhou-Jinhua-Quzhou Expressway forms an important part of expressway network in Zhejiang Province. It is not only the main fast channel connecting Hangzhou and Shaoxing but also a key channel for Shaoxing City to integrate into Hangzhou metropolitan area and to realize the integration of three districts. Simultaneously, it is also an important link of the outer ring expressway of Keqiao District, Shaoxing City.

STEC scientifically plans and carefully organizes the construction, solves the construction and technology difficulties, addresses the bad geological section, and then get through the construction bottleneck. Based on good construction organization, STEC reasonably allocates resources and keeps balance in construction. It takes environmental protection seriously, carries out green, environmental and high standard construction, and penetrates through forest land, reservoirs and streams. STEC is committed to construct a “safe, ecological and environmentally friendly” highways and contributes to the integrated and high-quality development in the Yangtze River Delta.

Business sector: Roads and bridges

Location: Anyang City of Henan Province

Commencement time: October 2021

Participation mode: BOT mode

Anyang-Luoshan Expressway is one of the 16 north-south vertical channels in the Henan Province Expressway Network Planning (2021-2035), connecting 9 cities and 16 counties in Henan Province. Upon its completion, the project will form a new vertical channel between the Beijing-Hong Kong-Macao Expressway and the Daqing-Guangzhou Expressway. It will connect the Beijing-Tianjin-Hebei urban agglomeration and Xiongan New Area in the north and the urban agglomeration in the middle reaches of the Yangtze River in the south. The project is of great significance for China to further strengthen inter-regional economic integration and relieve the traffic pressure on the Beijing-Hong Kong-Macao Expressway.

Covering a total length of 38.9 km, Bid SG-4 of the Yuan-Hebei provincial boundary to Yuanyang section (Lankao-Yuanyang Expressway) of the Anyang-Luoshan Expressway involves 1 hub, 3 interconnections, 1 service zone, 51 channels, 33 box culverts and 54 bridges. The standard design of the project is six lanes in two directions; the design speed is 120 km/h and the pavement width is 34.5 m. Builders have vigorously promoted the implementation and application of emerging technologies of smart construction site in Anyang-Luoshan Expressway project. The intelligent control has efficiently facilitated project construction. STEC introduces intelligent prefabricated box girder workshop and uses the independently developed bridge prefabricated component production information management platform so as to ensure that component production information can be tracked throughout the process and the quality can be controlled. Pavement construction information system assists the construction and thus realizes intelligent identification of pavement construction status and quality. In this way, the system promotes the integration mode of factory production, information management and intelligent control.

Business sector: Roads and bridges

Location: Lankao County of Kaifeng City and Fengqiu County of Xinxiang City in Henan Province

Commencement time: The main project is scheduled to commence on November 1st, 2022, (Subject to the actual commencement instruction), and the temporary steel trestle started on June 10th, 2022.

Participation mode: BOT mode

Project breakthrough: The subbridge superstructure of the Yellow River Bridge in this project adopts the whole hole erection of 100-m span steel concrete composite beam. This technology is another innovative breakthrough after the whole hole erection process of 80-m span steel beam of Mengzhou Yellow River Bridge in China. It will form a new achievement in bridge equipment research and development and installation technology.

The Lankao County of Kaifeng City and Fengqiu County of Xinxiang City in Henan Province starts from Lankao County, crosses the Yellow River to the west, and ends in Fengqiu County, with a total length of 30.263 km. The main line of the project adopts the expressway standards with six lanes in two directions, a subgrade width of 34.5 m, a design speed of 120 km/h. The Yellow River Bridge is as long as 9.104 km.

The maximum height of the main tower of the Yellow River Bridge is 160.5 m, with high spatial positioning accuracy and difficult line-type control. The foundation pile adopts the pile foundation with super depth and super large diameter (as deep as 106 m). The generous amount of concrete construction underwater tests STECs delicacy management. The subbridge superstructure of the Yellow River Bridge in this project adopts the whole hole erection of 100-m span steel concrete composite beam. This technology is another innovative breakthrough after the whole hole erection process of 80-m span steel beam of Mengzhou Yellow River Bridge in China. It will form a new achievement in bridge equipment research and development and installation technology.

The project serves as a key construction project of “13445” expressway engineering in Henan Province. Upon its completion, the project is of great significance for China to facilitate the strategy of the rise of central China, accelerate the development in "Central Henan Urban Agglomeration", promote the Zhengzhou metropolitan area, and advance the high-quality development in the Yellow River Basin.

Business Section:Airport

Location:Shanghai

Project Starting Date:2013

Construction Mode:Managing Contractor

Airspace Class: 4F Class Civil Airport

As one of China’s three largest international airports, Shanghai Pudong International Airport handles 60% of the total flights coming in and out of Shanghai. It serves the most international travelers among other domestic airports. STEC has been involved in several construction projects so far since 2003, in terms of airport runway, taxiway, and rainwater pumping stations. In order not to affect the airport’s daily operation, STEC has overcome challenges such as limited construction time and low visibility in nighttime during the construction. Currently, STEC are making all efforts in building the fifth runway and eastern tarmac. After the construction, Pudong Airport will work as a comprehensive transportation hub, linking domestic and international cities. This will continuously enhance the city’s comprehensive competitiveness, and the ability to serve the whole country and to link the world.

Business Section:Bridge

Location:Nanchang, Jiangxi Province

Project Completion Date:May 2015

Participating Mode:BT + Maintenance

Bridge Length:3.6 Kilometers

Jiangxi Nanchang Chaoyang Bridge, between the Nanchang Bridge and the ShengMi Bridge, is the major project of the south-central expressway crossing over the Gan River in the trunk road network plan. Its total length is 3.6 kilometers, including 1,560 meters that cross over Gan River. STEC invested, designed and built the bridge. We also undertook its daily maintenance, materializing “Full Life Circle Theory”. In terms of the design, after full consideration of the history and development of Nanchang, we formulated “Sail in Joint”, which means the bridge would have six towers and seven holes. The shape of the bridge looks like a Chinese character合, meaning tolerance and harmony. In the middle of the bridge, there are two viewing platforms which make it a pleasant experience to cross the river slowly. During the construction, we used the new technology of PC box girder with corrugated steel webs. It not only decreased the work of supporting structure, but also the work of building samples, bracket etc. The new technology was economical, and shortened construction period. Nanchang Chaoyang Bridge advanced the plan “One River with Two Shores” of Nanchang government. It further accelerates the construction of new Chaoyang city, and it is significant to the development of Hongjiaozhou District.

Business Section:Smart Transport

Location:Shanghai

Project Completion Date:2013

Participating Mode:Designing

Project Value:Cars Paying Toll without Stopping in Five Provinces and One City

Shanghai Electronic Toll Collection Project is a major civil engineering project. By using this toll system, cars can go through the gate in less than two seconds, five to ten times quicker than paying fees manually. STEC leads the industry in designing smart transport. After Shanghai government issued a paper on developing the highway ETC system in 2006, STEC is proud to be invited to design the 1st, 2nd and 3rd phases of the ETC project, providing comprehensive plans for the full application of the ETC system, and also assisting Shanghai to lead other cities in developing smart transport. We suggest the ETC project having toll charging and clearing center, card center, customer service system, toll charging branches, toll gate system, driveway system and car OBU system. We’ve also proposed an innovative ETC technique plan. That is, installing OBU with a single stored value card to let a car go through quickly on crowded roads to meet some cities’ requirements of high speed. Using traffic micro simulation software PARAMICS can optimize the setting of ETC driveways, railings, and card readers. With all these, crowded roads can be eased and clearance speed can be increased. After the 1st and 2nd phase construction, 190 ETC driveways were set up in 22 major toll gates and 64 subsidiary toll gates in Shanghai. After the 3rd phase, 79 more were installed, covering all the highway toll gates inside Shanghai. Cars can now pass through the Yangtze Delta Region (Shanghai, Jiangsu, Zhejiang, Anhui, Jiangxi and Fujian) without stopping, by using the ETC system.

Business Section:Airport

Location:Shanghai

Project Completion Date:09,2011

Construction Mode:Managing Contractor

Airspace Class:4E Class Civil Airport

After several years of expansion, Shanghai’s first civil airport, Shanghai Hongqiao International Airport is now one of China’s largest international airports. Its construction and operation fully embodies the idea of “developing a city’s airport is to develop an aviation city”. STEC has been involved in the construction of Hongqiao Airport as early as 1970s, including most of the construction work of the runway, taxiway and tarmac before 2005. In terms of the airport’s renovation, STEC has accomplished the task of asphalt paving on runways in 1991, 1998, and 2005, without affecting the airport’s daily operation. We have also renovated the eastern taxiway in 2000, and the eastern runway in 2011. The airport’s eastern runway renovation project not only made full use of its residual value, but also complied with the infrastructure procedure strictly, and ensured safety, high quality and high efficiency of the project during the whole construction process. This was led by the life cycle cost management concept, supported by technological innovation and guided by the airport’s operation.

Business Section:Airport

Location:Guangzhou, Guangdong Province

Project Completion Date:09,2000

Construction Mode:Managing Contractor

Airspace Class: 4F Class Civil Airport

Guangzhou Baiyun International Airport, a large-scale civil airport in Guangdong Provincial Capital Guangzhou, is one of the three largest airports in China. As one of the earliest companies taking part in the construction of the new Baiyun Airport, STEC has constructed many projects, including overhead bridges on airport’s highway, earthwork and drainage work in the flight area, China’s first taxibridge, tarmac, parking lot, and the third runway, witnessing the Baiyun Airport turning into one of three largest airports in China. Amongst which the flight area bridge project was honored the Tien-yow Jeme Civil Engineering Prize, National Green Building Innovation Award, and Shanghai Infrastructure Golden Prize. After more than ten years’ efforts, we’ve constructed several star projects at the airport, which largely improved the airport’s overall management abilities. The third runway project for the airport’s expansion, is built to the highest global standard, meeting 4F class aircraft usage specifications and able to accommodate the largest passenger aircraft model A380. The third runway was put into use in February, 2015, marking Guangzhou Baiyun International Airport the third domestic airport to have three runways, after Beijing and Shanghai.

Business Section:Smart Transport

Location:Shanghai

Project Completion Date:2010

Participating Mode:Designing

Project Value:Multi Agent Hongqiao Integrated Information Management System

The Information Management System of Shanghai Hongqiao Integrated Transport Hub collates information about several transportations such as airport, high speed train, maglev, subway, highway, public transportation and taxi. STEC established a mathematical model to analyze and evaluate the passenger flow in the hub and a smart transport management system, which helped the hub to collect the transportation information from surrounding area, monitor, control signals, and direct cars and people. An all-round transport management system is informative, detailed, scientific, automatic and efficient throughout the whole process. As Asia’s largest transportation hub, Hongqiao Integrated Transport Hub sets an example for the information management system, which was given the third prize of Shanghai Scientific Progress Awards and first prize of a similar awards organized by China Highway and Transportation Society.

Business Section:Road

Location:Shanghai

Project Operation Date:10, 1988

Participating Mode:Design + Build + Maintain

Road’s Length:20.5 kilometers

Shanghai-Jiading Expressway is the first expressway in China, linking Qilianshan Road in northwestern Shanghai in the South and South Jiading Gate in the north. The total length is 20.5 kilometers. Two interchanges, Nanxiang and Malu, were built along the expressway, which were designed, constructed and maintained by STEC. In terms of its linear design, we introduced perspective inspection method to check the expressway’s route planning and its plane/longitudinal linear displacement. Eventually the design team came up with a road planning solution that matches greatly with the expressway environment that significantly improved the driving experience. The two diamond-shaped interchange along the Shanghai-Jiading Expressway has proved to be a solution to less land utilization and lower project cost. The upper structure of the interchange is built with pretensioning cored slab beam, combined box beam and post-tensioning T beam. To reduce the numbers of expansion joints and improve the runway’s flatness and bridge utility, the bridge surface adopted simple supported beam system with continuous slabs on the top, while the substructure adopts pier foundation. During the construction, we successfully solved the problem of building structures on the soft soil with the aid of the new research finding “setting up embankments on soft soil foundation” In addition, our findings of “fly ash as the filling material of expressway embankments” was given the 1st prize of Shanghai Science and Technology Progress Award and “simulations on expressway traffic system monitoring” was awarded the 2nd prize. In 2014, STEC finished the renovation of Shanghai-Jiading Expressway. This “phoenix nirvana” will surely bring new life to the expressway and grant users a more comfortable driving experience. The completion of Shanghai-Jiading Expressway marks the history of China’s first expressway.

Business Section:Road

Location:Shanghai

Project Completion Date:10, 1994

Participating Mode:Design + MC + Maintenance

Road Length:47.7 kilometers

Shanghai Inner Ring Road, also known as Shanghai Inner Ring, is the earliest elevated highway constructed in the city, and has a nickname of “Shanghai’s First Ring”. Stretching 47.7 meters, the highway consists of 49 continuous transition curves and straight lines, linking Pudong and Puxi through Nanpu Bridge and Yangpu Bridge. It functions as a protective shell for the city center traffic. The segment of Puxi and Pudong opened to the pubic in 1994 and 2009 separately. The highway has four lanes in both directions, with a speed limit at 80 km/h. Since the construction of the Inner Ring Road, STEC took charge of constructing, designing, renovating the Inner Ring Road and maintaining its Puxi segment. In 1993, STEC took on the task of the first-stage construction and co-designing work of the Inner Ring Road, which was” Shanghai municipal No.1 project”. For the second-stage, we were in charge of the construction and design of the southwestern segment. In terms of the design, we carried out a research with Tongji University about how Shanghai Inner Ring Road’s southwestern segment connect the main roads. The research results significantly impacted the layout of the entire ring road and created lots of new ideas and successful experiences for the later construction of the large interchange in city center. In the new century, we have undertaken the work of designing and renovating the Inner Ring Road’s Pudong segment. Finally, all of the Inner Ring Road was open to the public. We also participated in renovating the ring road, and paving the asphalt layer to welcome the Expo. We also changed the 29 km of street lamps along the Inner Ring Road in Puxi segment. The new street lamps used the LED energy-saving light, with low power consumption, high lighting efficiency, and long service life. The energy-saving efficiency is up to 50%. The light can also withstand Beaufort wind scale. On top of which we created an integrated portable working device with anti wall-bumping. The device looks like a box, in which workers can construct. It can sharply reduce the noise. The innovation also won a national patent. The 2A, first phase of Shanghai Inner Ring Road project constructed by STEC was given the Shanghai Magnolia Quality Project Award in 1993.

Business Section:Road

Location:Shanghai

Project Completion Date:07, 2010

Participating Mode:Managing Contractor + Maintainence

Road Length:3.06 kilometers

Shanghai West Xianxia Road Construction Project, located in Hongqiao Integrated Transport Hub, is not only an important part of the road construction work of Hongqiao Integrated Transport Hub but also the biggest single project in Hongqiao municipal supporting project. The total length of the road is 3.06 kilometers. The construction should pass through some affiliated parts of the airport, such as two taxiways in east and west, runway blast pads, runway signal lamp strip. As such, the requirement of the project is very demanding as it has to meet the ground deformation level of the airport. Through the upgrading and innovation in techniques and facilities, we have set a precedence for large slurry shields to cross under shallow soil of the airport runway, which is also the first underpass through the working airport runway in China. We have tackled the key problems by conducting a research “The Key Technology For Slurry Shield with Big Diameter to Pass under Shallow Soil of Airport Runway.” during the construction. We managed a series of innovative results, and won three patents, two software copyrights and a construction technology certification. The project was also given the 1st Prize of Shanghai Science and Technology Progress Award. In addition, the project was honored with several awards, including the 1st prize of National Quality Construction Project, the 3rd prize of National Outstanding Project, and the golden award of Shanghai Municipal Projects. The completion of West Xianxia road successfully optimized and improved the functions and layout of Hongqiao Integrated Transport Hub, coordinated and boosted the regional development and improved the transportation system.

Business Section:Bridge

Location:Shanghai

Project Completion Date:Nov. 2005

Participating Mode:Managing Contractor + Maintenance

Bridge Length:32.5 Kilometers

Shanghai East China Sea Bridge is the first sea-crossing bridge in mainland China. Its total length is 32.5 kilometers, including 27 kilometers over the sea. STEC constructed the bridge, and is in charge of maintenance. While building this grand bridge, many advanced technologies were used. STEC’s technical staff overcame problems of anticorrosion, fabricating and installing huge concrete box girder, and GPS positioning. These technologies became the standard of building the long-span bridge. Shanghai East China Sea Bridge created many miracles. The 32.5 kilometers length makes it the longest sea-crossing bridge in the world. The two bridge towers are 159 meters’ high, which are the highest in domestic offshore cable-stayed bridge. There is 1.22 kilometers of deep sea dike between the Zhushan Island and the Big Turtle Island. This is also a breakthrough in bridge-building technology. The biggest wonder is the building speed. We used highly efficient construction techniques to overcome the severe situation in open sea, and finished the project within 3 years. As a pioneer of building long sea-crossing bridge, the project’s experience has been practiced widely on building the Hangzhou Bay Bridge and the Qingdao Bay Bridge. The opening of the Shanghai East China Sea Bridge started the building Yangshan deepwater port and speeding up the development of Shanghai international shipping center.

Business Section:Bridge

Location:Shanghai

Project Completion Date:May 2010

Participating Mode:Design + Maintenance

Bridge Length:5.8 Kilometers

Shanghai Minpu Second Bridge’s span is the longest one among the rail joint double-deck cable-stayed bridge with one tower in China. The total length of main bridge is 436.65 meters, and its top deck is road while the other lower deck is two-way light rail. STCE undertook its design and maintenance. Due to the bold design of the Minpu Second Bridge, many breakthroughs were achieved. A cargo ship with 3,000 tons’ load can go through the main hole safely even if it encountered the highest navigable water level once in every 300 years. The main pier is in the center of the river, constructed by fully welded steel truss plate beam structure. The main tower has two cable planes. The 251.4 meters’ span makes the bridge the longest span bridge with a single tower and one cable plane. This bridge also used new type of bridge pier in the form of the Chinese character 干, which was the first time in China. This design not only overcame land space restrictions, but also solved the problem of poor view while navigating, which was previously built in the form of the Chinese character 门. What’s more, we carried out experiments on seismic performance, and worked out the rules of typical single column and double deck bridge when encountering earthquake. This provided experience to build rail joint double-deck cable-stayed bridge. Shanghai MinPu Second Bridge takes a vital role in the development of Fengxian district, which attracts more investors to come. It also shortens the traffic time between Fengxian and Shanghai city center.

Business Section:Road

Location:Changzhou, Jiangsu Province

Project Completion Date:12, 2008

Participating Mode:BOT

Road Length:57.45 kilometers

Jiangsu Changzhou Elevated Highway, 57.45 km in length, is the first elevated highway in Changzhou, crossing over four new and old canal bridges and two Beijing-Shanghai railway bridges. To build the elevated highway on the basis of high standards, high demands and high tastes, we adopted the most advanced fish-bellied circular arc box beam in designing the box beam of the highway. It has the advantages of good overall performance, large torsion rigidity, and large span capacity. The normal pier adopted H-shaped column, which is not only delicate in appearance, but also clear and bright from watching under the bridge. We have positively adopted various energy-saving and green technologies. In terms of energy-saving, we installed embedded low-glare freeway ramp illumination system, which efficiently tackled problems of controlling glare, enhancing illumination level and evenness. It is the first time the system is widely used in China. In terms of land-saving, H-shaped and Y-shaped columns were adopted to save land. The deck space is 784,338 square meters, but the column occupation area is only about 5%. Other spaces were all designed for traffic lanes. We also introduced integrated smart traffic monitoring system by applying computing core technology, information technology, image transmission technology, and fiber optic network, to help drivers as well as the maintenance management unit know the real-time traffic condition through electronic screens. This project achieved a new high standard in terms of the investment scale, technological innovation, digital system, and modernized management. It was awarded the 1st prize and silver prize of National Outstanding Engineering Investigation Design. It was also given the China Construction Engineering Luban Award, and named as Jiangsu Province Model Construction Site and Jiangsu Quality Project.

Business Section:Bridge

Location:Shanghai

Project Completion Date:Nov. 2009

Participating Mode:Design + Managing Contractor + Maintenance

Bridge Length:16.63 Kilometers

Shanghai Yangtze River Bridge is the biggest rail joint cable-stayed bridge in the world, called “The First Bridge in Yangtze”. Its total length is 16.63 kilometers, and the main navigational hole’s diameter is 730 meters. STEC contracted, designed and built this bridge. We also undertook the daily maintenance. As one of the designers, we cooperated with Shanghai Municipal Engineering Design and Research Institute, bearing in mind the theory of “Design for Users”. We did our best to create and optimize every detail in order to unleash aesthetic value at the same time achieving transportation function. We reserved railway space and kept pace with six traffic lanes in both directions, which is the first case in the world. The main tower is 212 meters high without beam, which is the first case in China. In other words, when building this bridge, we tried new skills and techniques, realizing the perfect combination of strength and beauty. What’s more, the whole line of the bridge was designed into a shape of “S” considering its influence to water flow, and functional requirements. The “S” shape also meets the need of beauty and environmental protection. Based on these creative theories, we forged several word-leading skills which were used in bridge building for the first time. For one thing, the cable-stayed bridge, whose main span is 730 meters in length, used new separated steel box girder. For another, there are 700 meters high pier area that used a series of combining box-girder bridge whose main span is 105 meters. The project of fabricating the whole hole in advance is also a new practice. Asphalt on the bridge floor is only 4 centimeters, so its deadweight is light. We used Germany MOBA MaticII as the method of controlling the evenness. We also researched for long-lasting asphalt, and overcame the influence of marine climate to the bridge floor, in this case, we can ensure the quality. Shanghai Yangtze River Bridge fixed the situation of over a thousand years, there was no road pavement from Chongming Island to the mainland.

STEC 版权所有 沪ICP备15043468号-3

沪公网安备 31010402005457号

沪公网安备 31010402005457号